When I purchased this house, a full inspection was performed on the HVAC system; other than requiring a minuscule amount of R-22 and cutting back branches around the condensing unit, it was in perfect working order. This furnace is more than 30 years old; needless to say, it will eventually need to be replaced, if not due to failure, for energy efficiency. The home inspector recommended that I clean it well and get the humidifier fixed. As it turned out, the humidistat was so filthy that it no longer sensed properly. A quick cleaning and the replacement of the evaporating pad fixed that completely.

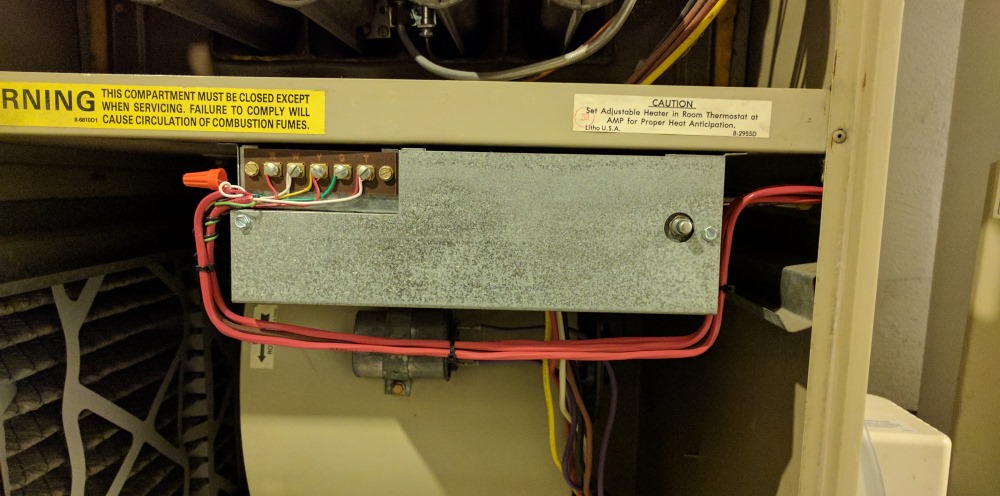

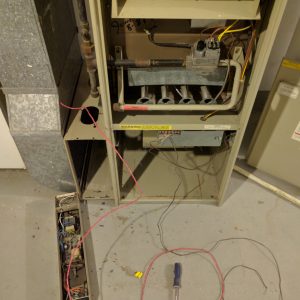

After cleaning the humidifier, I opened the furnace to find that years of wiring and rewiring created a rat’s nest of cabling and the cover no longer fit over the wiring bundle. I was also able to see the humidifier wired directly to the transformer so it would run continuously, needlessly dumping several gallons of water down the drain per hour. It is now wired into the heating circuit so it only triggers when heating and the blower motor is running. In addition to that, the electrostatic air filter was no longer in use and had been replaced with a paper filter. I actually prefer this, but they never removed power to the unit making it potentially dangerous to service if you aren’t being careful and expect it to be dead. I removed the whole control unit and back-fed the old circuit so it is nothing more than an over-glorified filter box. I also organized the wiring at the control unit so a cover could once again be installed. This final setup is featured at the very top.

After cleaning the humidifier, I opened the furnace to find that years of wiring and rewiring created a rat’s nest of cabling and the cover no longer fit over the wiring bundle. I was also able to see the humidifier wired directly to the transformer so it would run continuously, needlessly dumping several gallons of water down the drain per hour. It is now wired into the heating circuit so it only triggers when heating and the blower motor is running. In addition to that, the electrostatic air filter was no longer in use and had been replaced with a paper filter. I actually prefer this, but they never removed power to the unit making it potentially dangerous to service if you aren’t being careful and expect it to be dead. I removed the whole control unit and back-fed the old circuit so it is nothing more than an over-glorified filter box. I also organized the wiring at the control unit so a cover could once again be installed. This final setup is featured at the very top.

Seeing that I plan to rewire the entire house, I didn’t want to leave any stone unturned. Even though the system was working well I decided to run new control wiring. I was able to replace the control wiring to the humidifier and the A/C unit with new 18/2 solid core wire as the devices called out. I also ran 18/5 solid core to the thermostat and rewired the whole system so it used the standard color scheme.

The two remaining items that absolutely needed to be fixed were the condensate line and feeder circuit. The furnace was wired into the branch circuit that fed the entire first floor. Having put a microwave in the kitchen, the breaker would pop with frequency (every time the heat would kick on while you were warming food). I ran a brand-new feeder circuit to a 15A fused power module and added a power source for a condensate pump. After completing the new tie-in, I removed the condensate pipe that ran across the basement floor to the drain and installed a pump instead that drains into the basin across the room.

This whole process is outlined in the photo gallery below and is a massive improvement. Now that water doesn’t pool around the rusted basement drain I am hoping it will last another year or two until I can finally cut out the floor to replace it with something better. You’ll also see a random photo of a vent behind a hole in the wall. I have been tracing back leaks in the duct work and this is one example. A vent was moved when the basement was finished. Instead of sealing the hole, a loose piece of metal was laid against it. This leaked badly and was heating above the drop ceiling. I am hoping that fixing these issues properly will help lower heating costs in this house a fair amount.